Activated Carbon Tower

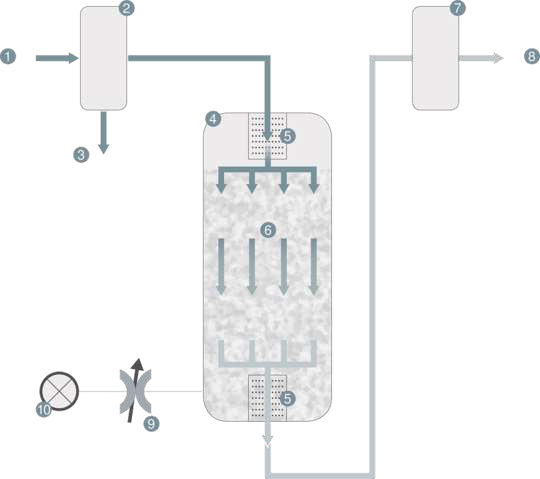

Activated Carbon Towers efficiently remove oil vapor from compressed air using inlet and outlet diffusers for uniform flow distribution. EcoEnserve adsorbers provide high-quality, oil-free compressed air that is odorless and tasteless. Installed after drying and pre-filtration, they achieve ISO 8573-1 Class 1 residual oil standards, ensuring reliable protection for sensitive processes. Activated Carbon Towers in Oxygen and Nitrogen Gas Production Activated carbon towers are essential in oxygen and nitrogen production, removing contaminants, oils, and organic compounds during air separation to achieve high-purity gases. EcoEnserve towers improve efficiency with their high absorption capacity and durability.

Working Process & Key Benefits:

- Technically Oil Free Compressed Air:

- In order to meet the strictest Class 1 compressed air purity class requirements as stipulated by industrial standard ISO 8573-1, compressed air should have a residual oil content no higher than0.01 mg/m³.

- Class 1 compressed air is therefore significantly cleaner than typical ambient air. For this reason, compressed air treatment is essential irrespective of the compression method that is used to produce it.

- In order to achieve this level of purity, more is needed than to simply remove the residual fluid oil content via filters. The vapour component also needs to be retained by means of adsorption on activated carbon. High performance activated carbon adsorbers can achieve residual oil content significantly lower than the threshold value for Class 1 compressed air purity

- Energy Savings:

- Generously-dimensioned flow diameters, together with stainless steel flow diffusers, ensure even flow distribution with an exceptionally low-pressure loss no higher than 0.1 bar. As a result, the compressor discharge pressure of upstream compressors, as well as the energy costs for compressed air production, can be kept as low as possible.

- Exceptional Reliability:

- Activated carbon adsorbers utilise a high quality and generously sized activated carbon filling. Optimised for gas purification, the special type of activated carbon is fine pored and possesses an exceptional retention capacity.

- Provided as original equipment, as well as for maintenance, the carbon used is abrasion-resistant, low-dust and has minimal ash content. Furthermore, specially designed stainless steel flow diffusers ensure even flow distribution throughout the activated carbon bed. Consequently, the exceptional compressed air purity is reliably assured for up to 12,000 full load hours, or a maximum of five years.

- Low Life Cycle Cost:

- When it comes to continuous compressed air demand, Eco Enserve Activated carbon adsorbers are cost effective compared to typical activated carbon filters.

- Thanks to significantly longer service intervals, their life-cycle costs in the third year can equal those of high quality activated carbon filters. In the following years they are by far the more cost-effective alternative. This advantage is further bolstered by better compressed air availability resulting from the lower number of necessary service visits. Basis: Costs for investment, service (material, work and disposal), with the following replacement intervals: ACT activated carbon filling 12,000 operating hours, particulate filter 6,000 operating hours, activated carbon filter 1,000 operating hours; annual interest payments over 10 years.

- Minimal Pressure Loss:

- Activated carbon adsorbers feature generously sized cross-section pipework and tanks. They consequently operate with differential pressures (dp) no higher than 0.1 bar

- Long Activated Carbon Service Life:

- Generous fill volumes, high quality activated carbon and stainless steel flow diffusers allow the activated carbon filling in activated carbon adsorbers to deliver an exceptionally long service life of up to 12,000 full load hours, or a maximum of five years, without being changed

- Accessories: Compressed Air Filters [Optional]

- Activated carbon adsorbers should always be equipped with filters. Eco Enserve always recommend to install as pre- and downstream filters, they ensure maximum service life of the activated carbon and, with minimal pressure loss, prevent carbon dust from being entrained in the cleaned compressed air

- Food-Beverage

- Medical

- Chemistry

- Pharmaceutical

- Process

- Metal Industry

- Air Treatment

- Electronics

- Gas Generator Plants

- Petrochemical

- Easy Installation

- Optimal Adsorption of Oil Vapour (Hydrocarbons)

- Optimized Flow Distribution

- Low pressure loss, less than 0.1 bar

- Residual oil content up to 0.003 mg/m3

- 12,000 hours of Average activated Carbon Service Life

- Low Dust level at outlet through Stainless steel Flow Distributor

- Maximum Operational Reliability

Require a solution to your problems?

Want to get in Touch?

Have an idea? Do you need some help with it? Eco Enserve wouid love to

help you!

Kindly click on “CONTACT US” to reach us and share your query.