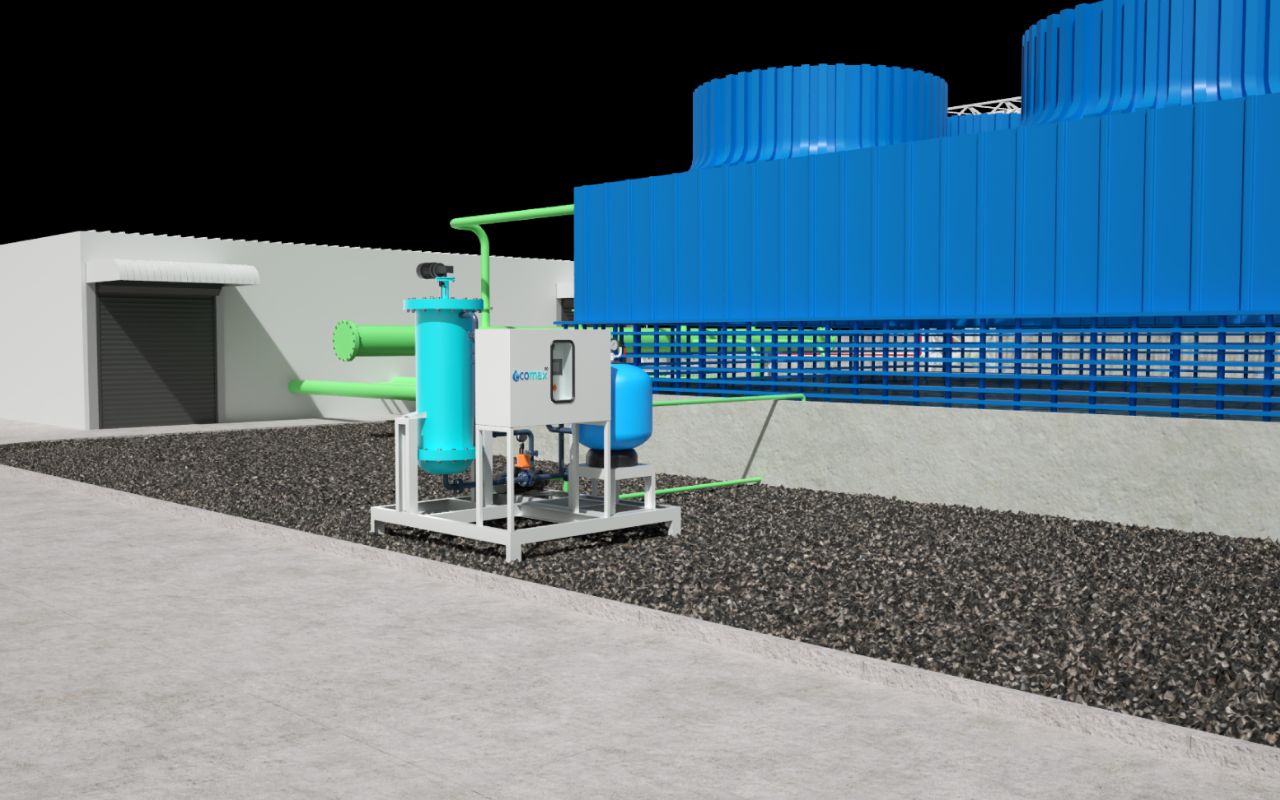

Electrolytic CT Water Treatment System

Electrolytic CT (Cooling Tower) Water Treatment System is a chemical less treatment system to treat cooling tower circulation water. It works on the principle of electrolysis of water and water is treated in Electrolytic Reactor. This system is designed to prevent scale buildup, control corrosion, and inhibit microbial growth, thereby enhancing the efficiency and lifespan of the cooling tower.

- Electrolysis Process

- Scale Prevention

- Corrosion Control

- Microbial Control

- Environmental and Operational Benefits

Working Process & Key Benefits:

- Electrolysis Process:

- The system uses an electrolytic cell, where a low-voltage electrical current is applied to water as it passes through the cell.

- This current causes a series of chemical reactions that alter the properties of the dissolved minerals and other contaminants in the water.

- Scale Prevention:

- The electrolytic process precipitates calcium carbonate (CaCO₃) and other minerals out of the water, preventing them from forming scale on the heat exchange surfaces.

- These precipitates can then be removed through filtration or regular blowdown (a process of removing a portion of the water with high concentrations of minerals).

- Corrosion Control:

- The process also alters the water chemistry to create a protective film on metal surfaces, which helps in reducing corrosion.

- It may involve the formation of a passive layer that protects the metal from further oxidation.

- Microbial Control:

- Electrolysis can generate oxidants like chlorine or hypochlorous acid in the water, which helps in controlling the growth of algae, bacteria, and other microorganisms.

- This reduces the biofouling that can occur in cooling towers.

- Chemical Reduction: This system reduces or eliminates the need for chemical additives commonly used in traditional water treatment methods, such as anti-scalants, biocides, and corrosion inhibitors.

- Water Efficiency: By managing scale and corrosion effectively, the system can reduce the amount of water required for blowdown, thereby conserving water.

- Energy Efficiency: Clean heat exchange surfaces improve the efficiency of the cooling tower, reducing energy consumption.

- Industrial Cooling Towers: Used extensively in industrial settings where cooling towers are critical for maintaining process temperatures.

- Commercial Buildings: Applied in large HVAC systems in commercial and institutional buildings.

- Power Plants: Used in power generation facilities where cooling towers play a crucial role in the cooling process.

- Lower Operating Costs: Reduced chemical usage and improved energy efficiency can lead to significant cost savings.

- Environmentally Friendly: Reduces the environmental impact by minimizing chemical discharge and water consumption.

- Improved Equipment Longevity: By preventing scale, corrosion, and biofouling, the system helps extend the life of cooling tower components.

Require a solution to your problems?

Want to get in Touch?

Have an idea? Do you need some help with it? Eco Enserve wouid love to

help you!

Kindly click on “CONTACT US” to reach us and share your query.